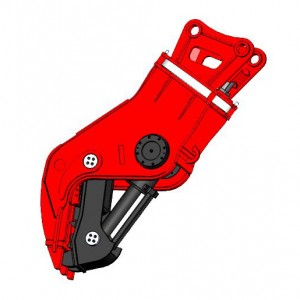

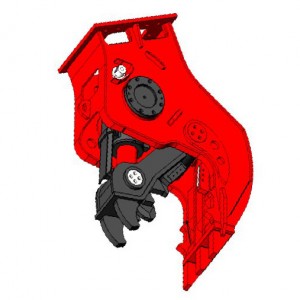

Concrete Crusher Hydraulic Pulverizer For Demolish Constructions And Buildings

Installation elements

1. Turn the operation button of the QUICK COUPLER to "release", and then operate.

2. Make the fixed jaws of the QUICK COUPLER slowly grasp the upper shaft of the hydraulic crusher.

3. Move the QUICK COUPLER slowly in the opposite direction of the upper shaft of the hydraulic crusher.

4. Make the jaws of the QUICK COUPLER and the upper shaft of the hydraulic crusher completely stuck.

5. Turn the operation button of QUICK COUPLER to "Connect", and then operate.

6. If the hydraulic crusher pliers can turn, the installation can be completed. After completing the installation and then insert the safety shaft.

7. Two gun head pipe connected to the excavator. (The same pipeline installation and crushing hammer, if the original car has been installed crushing hammer, direct use (Crushing hammer pipeline can be)

8. Start the excavator, after the excavator power smoothly, before and after pressing the foot valve, observe the hydraulic crushing pliers open and close normal. Note: the first cylinder expansion stroke of no more than 60%, so repeatedly more than 10 times, to exclude the residual gas in the cylinder wall and gasket cavitation damage.

9. Normal installation is completed.

Inspection and maintenance essentials

1. When overhauling, never put your hand inside the machine, and don't touch the rotating won't with your hand to prevent injury;

2. When disassembling and assembling the cylinder, be careful not to let the magazine enter the cylinder.

3. When carrying out maintenance, please clean the mud and impurities at the oil filling place, and then carry out oil filling.

4. Fill grease once every 10 hours of work.

5. Check the oil cylinder for oil leakage and oil circuit wear every 60 hours.

6. Check whether the bolt is loose every 60 hours of work.

product Specification

| MODLE | UNIT | BRTP-06 | BRTP-08A | BRTP-08B |

| WEIGHT | kg | 1100 | 2300 | 2200 |

| MAX JAW QPENING | mm | 740 | 950 | 550 |

| MAX SHEARING FORCE | T | 65 | 80 | 124 |

| BLADE LENGTH | mm | 180 | 240 | 510 |

| OIL FLOW | Kg/㎡ | 300 | 320 | 320 |

| SUITABLE EXCAVATOR | T | 12-18 | 18-26 | 18-26 |